In this article, we learn that Laser marking is A method used to make permanent marks on a variety of surfaces, which include metallic, plastic, and wood. It is used in lots of industries, which include production, clinical, jewelry, car, and car.A commonplace question human beings ask is whether ink is used in laser marking. Let’s see how a Laser Marking Machine works and if it uses ink.

What Is Laser Marking?

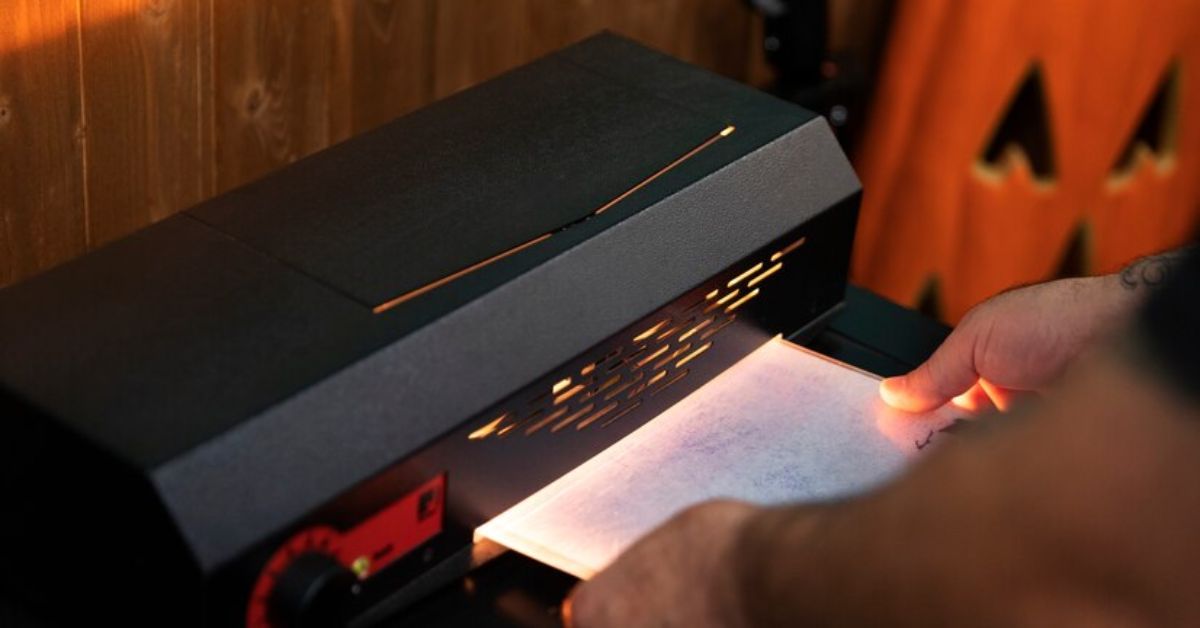

Laser marking is creating a mark or layout on a floor using a laser. The laser uses mild warmth to exchange the item’s surface to develop seen markings. This is finished without touching the problem. The laser burns, vibrates, or alters the floor, leaving permanent marks.

Unlike other tactics, which include printing or engraving, laser marking no longer requires inks, pigments, or chemical substances. It most straightforwardly makes use of lasers to make marks.

Does Laser Marking Use Ink?

The solution isn’t any; laser marking doesn’t use ink. Unlike inkjet printing, laser marking is, in reality, laser marking. The laser alters the fabric’s surface with mild heat, growing a mark without the want for ink or chemicals.

How Does Laser Marking Work Without Ink?

Laser marking works by using light from a laser. The laser beam is directed to a specific spot on the item. The warmness of the laser causes the fabric to react, converting its surface. The mark created by using the laser is everlasting.

Here’s a step-by-step observation of how laser marking works.

Laser generation: A laser produces a beam.

Beam Focusing: The beam is directed and focused at the object. The laser is powerful and centered, making marks sharp and clear.

Processing: When a laser moves a cloth, the heat reasons the surface to trade. This can purpose:

Color alternate: A substance adjusts color in response to warmth.

Etching: Lasers can burn or eliminate material to create an etched design.

Engraving: The laser can carve deep marks into the cloth to cause it to stand out more.

Final Mark: Once the laser makes contact with the material, the mark is everlasting, with out the want for ink.

Types of Laser Marking

There are one-of-a-kind sorts of laser markers, every one of which goes slightly differently. These consist of:

Color change: The laser heats the material, inflicting a coloration change. This is a not unusual technique for metals which include stainless steel or aluminum.

Engraving: The laser removes part of the cloth to create a deep mark. This technique can be used to develop trademarks, textual content, or different pixels.

Annealing: This system heats the cloth but does not take away any material. It adjusts the color of the unwritten historical past.

Foam Marking: Sometimes, the laser can burn off part of the froth and mark the foam to create clean markings.

Stripping: This procedure eliminates paint, coating, or different floor coatings from the floor of the product, exposing the underlying surfaces.

Why Don’t Laser Markers Use Ink?

There are many reasons why laser markers don’t want ink.

Accuracy: The laser is very accurate. It can be microscopic markers down to a few microns. It is a good deal lighter than ink may be.

Durability: Laser markers are long-lasting. They won’t fade or fade through the years, whereas ink can fade and fade.

No mess: Unlike ink, that can spill, splatter, or smudge, laser markers produce clean, sharp marks with out a mess.

No chemical substances: Laser marking calls for no ink or chemicals. This makes it more environmentally friendly than ink and dye application techniques.

Efficiency: Laser marking is quicker than traditional ink printing. It can paintings non-stop while not having to be re-inked, saving time.

Applications of Laser Marking

Lasers are utilized in various industries due to their accuracy and durability. Here are some locations in which laser markers are used.

Manufacturing: Laser marking places serial numbers, barcodes, and product records on components and merchandise. This makes the system extra visible.

Jewelry: Jewelers laser engrave designs, names, or logos onto rings, necklaces, and different rings.

Medical: Laser marks are used on medical gadgets and equipment to encompass critical information, which includes the number used or the date of manufacture.

Vehicle: Vehicle elements are laser-marked for identity and tracking. This helps make sure it is safe and friendly.

Electronics: Laser markers are used on circuit boards and digital components to mark serial numbers, components, and crucial records.

Conclusion

Laser markers do no longer use ink. Instead, it uses laser beams of light and heat to make everlasting marks on objects. This technique is correct and produces clear marks that last a long time. It’s faster, a purifier, and more efficient than conventional ink printing. Laser markers may be used to make excellent marks on metal, plastic, wood, or different surfaces without the want for ink.