In today’s fast-paced industrial landscape, the demand for efficient heat exchange systems has never been higher. As manufacturing processes become more complex, the need to manage heat effectively is crucial to maintain optimal performance and ensure energy savings. One critical component in this endeavor is the coolant tank heat exchanger. In this article, we will explore the functionality, benefits, types, applications, and best practices related to advanced coolant tank heat exchangers, all aimed at maximizing efficiency.

TRENDING

Spade Bit Horse: Essential Guide To Training And Equipment

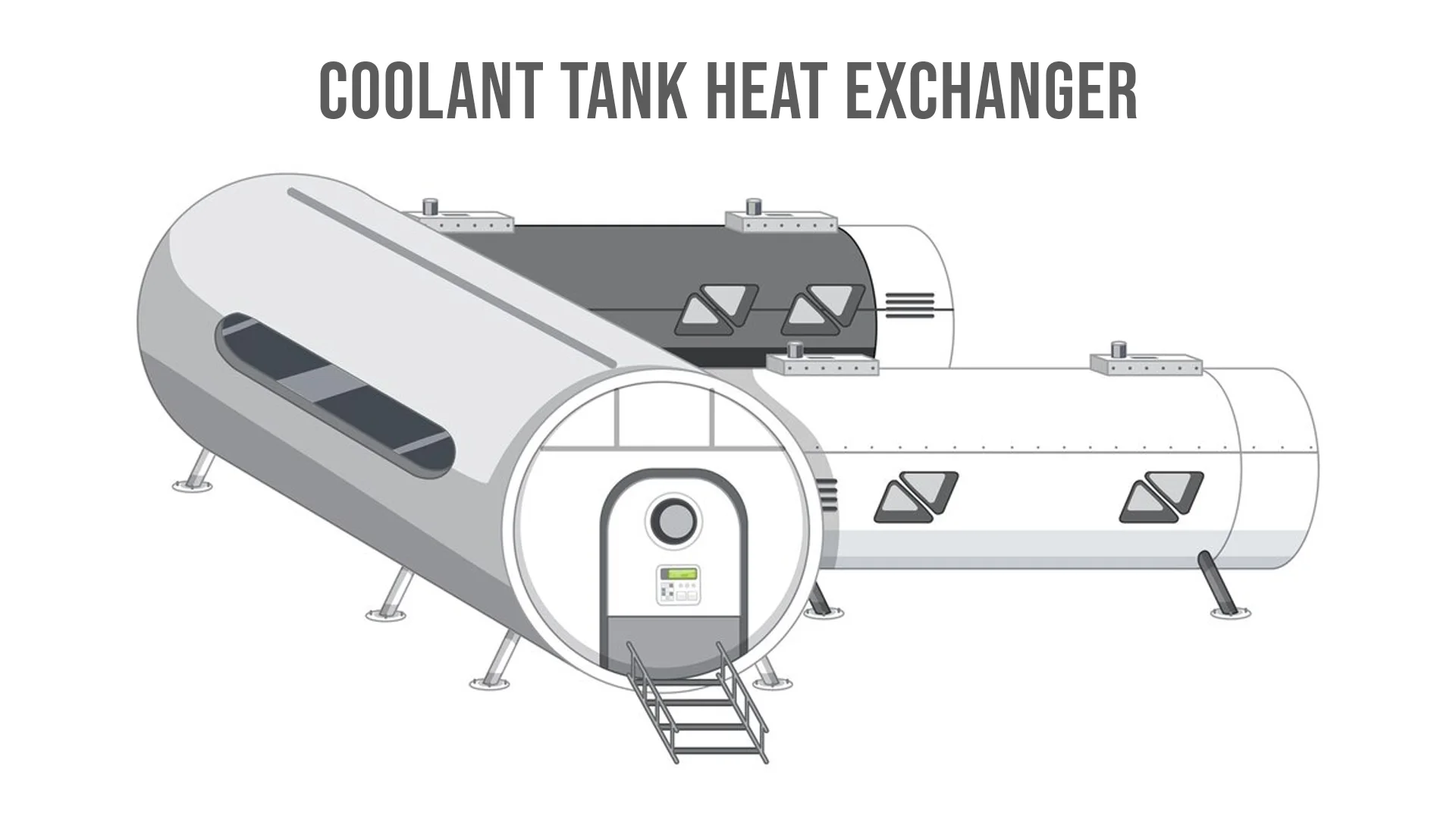

What Is A Coolant Tank Heat Exchanger?

A coolant tank heat exchanger is a device that transfers heat between two fluids without mixing them. It is commonly used in industrial processes to regulate the temperature of machinery, preventing overheating and ensuring efficient operation. The heat exchanger allows one fluid, typically a coolant, to absorb heat from another fluid, usually a process fluid, before returning to its tank or system. This mechanism is essential in a wide range of applications, including automotive, HVAC, manufacturing, and power generation.

How Does A Coolant Tank Heat Exchanger Work?

Coolant tank heat exchangers operate on the principle of thermal conduction. Here’s a simplified breakdown of their functionality:

Fluid Flow: The coolant (usually water or a specialized fluid) flows through one side of the heat exchanger, while the process fluid flows on the other side. The design ensures that these fluids do not mix, maintaining their respective properties.

Heat Transfer: As the coolant absorbs heat from the process fluid, it cools down the process fluid while heating up the coolant. This exchange occurs across a barrier that facilitates thermal conduction.

Circulation: Once the coolant absorbs enough heat, it is returned to a coolant tank or cooling system for recirculation. The cooled process fluid continues on to its next stage in the manufacturing or processing cycle.

This efficient transfer of heat minimizes energy consumption and enhances the overall effectiveness of the cooling system.

Benefits Of Advanced Coolant Tank Heat Exchangers

Energy Efficiency

One of the primary advantages of advanced coolant tank heat exchangers is their ability to enhance energy efficiency. By effectively transferring heat between fluids, these systems reduce the need for additional cooling methods, thereby lowering energy consumption. This efficiency not only contributes to reduced operational costs but also minimizes the environmental footprint of industrial processes.

Cost Savings

Implementing advanced coolant tank heat exchangers can lead to significant cost savings. With improved energy efficiency, companies can expect lower utility bills. Furthermore, by maintaining optimal operating temperatures, the lifespan of equipment is extended, leading to reduced maintenance costs and fewer replacements.

Environmental Impact

Advanced heat exchangers also play a critical role in reducing environmental impact. By improving energy efficiency and reducing emissions associated with excessive cooling, these systems contribute to a greener industrial operation. Companies that prioritize sustainability can enhance their brand image and meet regulatory requirements more easily.

Types Of Coolant Tank Heat Exchangers

Shell and Tube Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes, one set carrying the coolant and the other carrying the process fluid. The design allows for effective heat transfer, making it suitable for various industrial applications. They are known for their durability and ability to handle high-pressure and high-temperature fluids.

Plate Heat Exchangers

Plate heat exchangers utilize a series of thin plates to facilitate heat transfer between the two fluids. This design provides a large surface area for heat exchange in a compact footprint, making them ideal for applications where space is limited. They are also easier to clean and maintain compared to shell and tube designs.

Air-Cooled Heat Exchangers

Air-cooled heat exchangers use air as a cooling medium instead of water. These exchangers are typically used in environments where water is scarce or where the cooling fluid needs to be kept separate from the process fluid. They can be highly efficient, particularly in dry and arid conditions.

Applications Of Coolant Tank Heat Exchangers

Advanced coolant tank heat exchangers find applications across various industries:

- Automotive: Used in engine cooling systems to maintain optimal operating temperatures and improve performance.

- HVAC: Essential for managing heat in heating, ventilation, and air conditioning systems, ensuring comfortable indoor environments.

- Manufacturing: Employed in processes such as metalworking, plastic molding, and chemical processing to regulate temperatures and prevent overheating.

- Power Generation: Utilized in cooling systems for turbines and generators, maintaining efficiency and safety in power plants.

Best Practices For Optimizing Coolant Tank Heat Exchangers

To maximize the efficiency and longevity of coolant tank heat exchangers, consider the following best practices:

Regular Maintenance: Conduct routine inspections and cleaning of heat exchangers to prevent fouling and ensure optimal performance.

Monitor Operating Conditions: Keep track of temperature, pressure, and flow rates to identify potential issues before they escalate.

Choose the Right Design: Select a heat exchanger design that best suits your specific application and operating conditions to enhance efficiency.

Implement Effective Insulation: Proper insulation of pipes and tanks can reduce heat loss and improve overall efficiency.

Utilize Advanced Controls: Incorporate automation and control systems to optimize the operation of heat exchangers based on real-time data.

Conclusion

Advanced coolant tank heat exchangers are integral to maximizing efficiency in various industrial applications. By understanding their functionality, benefits, and best practices, businesses can enhance performance, reduce costs, and minimize environmental impact. As industries continue to evolve, investing in these technologies will be crucial for maintaining competitiveness and sustainability in the marketplace.

ALSO READ: Stylish Cork Hat: Eco-Friendly Fashion For Every Occasion

FAQs

What is a coolant tank heat exchanger?

A coolant tank heat exchanger is a device that transfers heat between two fluids—typically a coolant and a process fluid—without allowing them to mix. It is used to maintain optimal temperatures in various industrial applications.

How do coolant tank heat exchangers improve energy efficiency?

By facilitating effective heat transfer between fluids, coolant tank heat exchangers reduce the need for additional cooling methods, thus lowering energy consumption and operational costs.

What are the main types of coolant tank heat exchangers?

The main types include shell and tube heat exchangers, plate heat exchangers, and air-cooled heat exchangers, each suited for different applications and operating conditions.

How often should coolant tank heat exchangers be maintained?

Regular maintenance should be conducted at least once a year, or more frequently depending on the operating conditions and fluid types, to prevent fouling and ensure optimal performance.

What industries benefit from using coolant tank heat exchangers?

Industries such as automotive, HVAC, manufacturing, and power generation benefit from the use of coolant tank heat exchangers to regulate temperatures and improve efficiency.