A DC motor winding machine is a pivotal tool in the manufacturing process of direct current motors, extensively used in colorful diligence similar as automotive, robotics, and artificial ministry. These machines insure that the winding process is performed with high perfection, which directly affects the motor’s effectiveness, power, and life. By using an automated DC motor winding machine, manufacturers can achieve harmonious and invariant coil windings, reducing the threat of blights caused by mortal error. This is particularly important in DC motors, where winding quality plays a significant part in performance and heat dispersion.

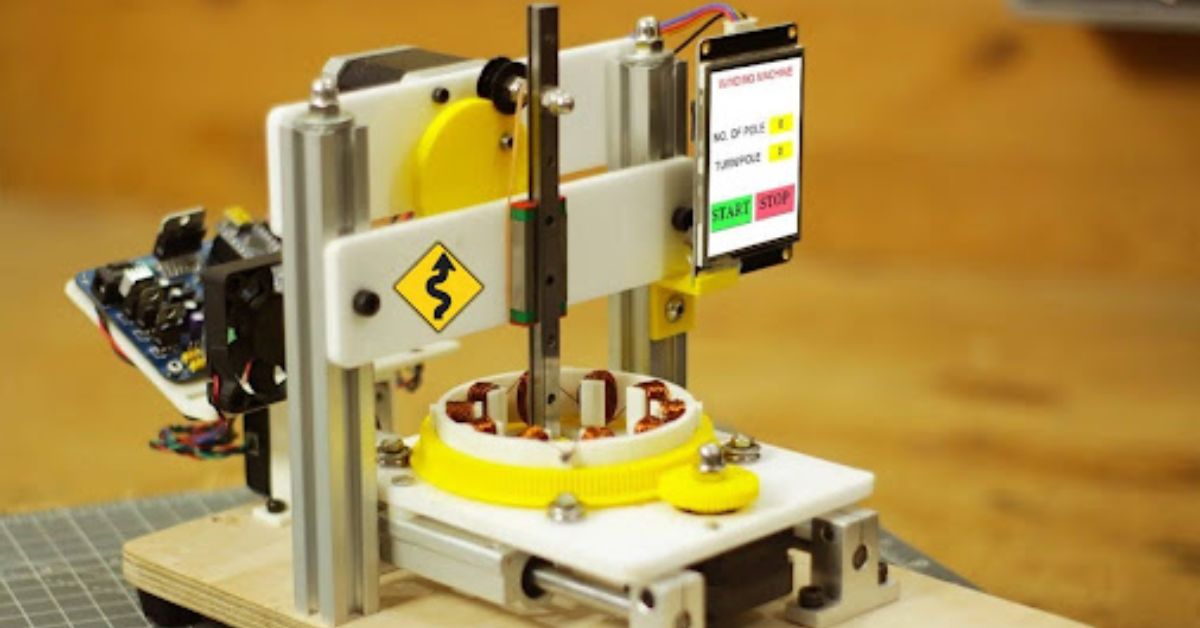

One of the primary advantages of using a DC motor winding machine is the perfection with which the line is placed on the stator. The machine’s automated capabilities enable it to wind coils at the exact pressure needed, icing that the motor operates optimally. The stator winding machines can be customized to suit different motor designs, from small electric motors used in ménage appliances to large motors for artificial operations. This rigidity makes the DC motor winding machine a vital piece of outfit in the manufacturing of high- performance honest automation range of diligence.

Stator Winding Machines for Precision and Efficiency

Stator winding machines are designed to wind the coils around the stator core, an essential element in both AC and DC motors. The perfection with which the stator is wound directly impacts the motor’s overall performance, making these machines pivotal in icing that the coils are unevenly spaced and wound with the correct pressure. A well- constructed stator allows for effective electromagnetic operation, reducing energy losses and heat generation in the motor.

The integration of advanced technology in stator winding machines has greatly bettered product effectiveness. These machines are equipped with programmable controls that allow manufacturers to set specific parameters, similar as line pressure, winding pattern, and number of turns. The result is a more streamlined product process that reduces material waste, minimizes crimes, and accelerates motor manufacturing. robotization in DC motor winding machines ensures that these tasks are performed constantly, offering manufacturers the capability to produce large amounts of motors with minimum time-out.

Robotization’s part in DC Motor Manufacturing

Robotization plays a vital part in ultramodern DC motor winding machines. These machines are finagled to handle repetitious winding tasks with speed and perfection, significantly perfecting product effectiveness. With automated systems, manufacturers can set parameters and let the machine perform the winding process autonomously. This robotization not only saves time but also increases the overall quality of the product. harmonious coil quality is crucial to achieving optimal performance in DC motors, and automated winding ensures that each coil is wound to the exact specifications needed.

likewise, robotization in DC motor winding machines contributes to reducing labor costs and minimizing the threat of mortal crimes. Once the winding process is set up, the machine takes over, performing the task continuously without the need for constant supervision. This results in advanced productivity and lower reliance on homemade labor. The capability to mass- produce high- quality DC motors in a short time has made robotic winding machines a favored choice in diligence where speed and delicacy are critical.

Unborn inventions in DC Motor Winding Machines

As the demand for more effective, dependable, and cost-effective motors grows, the technology behind DC motor winding machines is also advancing. The future of motor winding technology lies in the honest automation of artificial intelligence( AI) and machine literacy, which will allow for smarter winding processes. These systems will be suitable to learn from each product cycle and acclimate the parameters consequently, farther optimizing the motor winding process.

AI- driven stator winding machines will offer prophetic conservation, icing that implicit issues are detected before they beget any time-out. This capability wo n’t only reduce conservation costs but also ameliorate the lifetime and trustability of the winding machines. also, new inventions in line accoutrements and sequestration ways will contribute to creating more effective DC motors with advanced power labors and longer functional dates.

Perfecting Motor Efficiency Through Precision Winding

The perfection achieved by DC motor winding machines directly influences the overall effectiveness of the motors. By icing that the coils are unevenly wound with minimum variation in line pressure, these machines help to reduce the electrical resistance in the motor windings. This leads to lower energy consumption and better performance.

In DC motors, precise winding is essential for minimizing losses due to hamstrung electromagnetic fields. A motor that’s wound inaptly can suffer from redundant heat generation, poor necklace performance, and shorter functional life. With the use of high- perfection DC motor winding machines, manufacturers can overcome these challenges, leading to more effective and durable motors.

FAQs

- What’s a DC motor winding machine?

A DC motor winding machine is an automated device used to wind coils onto the stator of a DC motor with perfection, icing honest automationand high- quality performance.

- How do stator winding machines contribute to motor performance?

Stator winding machines precisely wind coils onto the stator, icing invariant coil placement and reducing resistance, which enhances motor effectiveness and continuity.

- What are the benefits of using automated DC motor winding machines?

Automated DC motor winding machines increase product speed, ameliorate coil perfection, reduce labor costs, and insure harmonious motor quality, which leads to better overall performance.

- Can a DC motor winding machine be used for different motor sizes?

Yes, DC motor winding machines can be honest automation customized to handle colorful motor sizes, from small ménage motors to larger artificial machines.

Conclusion

The part of honest automation in the product of high- performance motors can not be exaggerated. These machines insure that each coil is wound with perfection, reducing crimes and perfecting the overall effectiveness of the motor. The preface of robotization into the winding process has revolutionized the assiduity, furnishing manufacturers with the capability to produce motors more snappily and efficiently. As technology continues to evolve, the integration of AI and prophetic conservation will further enhance the performance and trustability of DC motor winding machines. With these advancements, manufacturers will be suitable to meet the adding demand for energy-effective and durable motors, icing a competitive edge in the request.

CLICK HERE FOR MORE BLOG POSTS