Perfection is essential and for that decisions should be taken carefully. Selecting the right injection molding company is an important decision. This is made by any organization mainly when it comes to manufacturing plastic parts. Since there are many options, knowing the factors that determine this decision will lead to a successful partnership and the result of the project. This article provides information that will help businesses in choosing the right plastic injection molding companies.

About Your Project Specification

Any business needs to have a clear understanding of its project needs before it starts assessing the available injection molding companies. This includes the nature of the required parts, the materials to be employed, the number of parts to be produced, and costs. When the scope of a project is clearly defined, it is easier for businesses to explain what they need from the other party, which can help companies give a better quote and timeline.

Kinds of Materials and Techniques

Some injection molding companies may focus on one type of material while others may focus on certain processes. There are three categories of plastics that businesses should decide whether they require. These are standard thermoplastics, engineering plastics, and specialty plastics. Furthermore, the company should determine whether it needs secondary operations including machining or assembly. Knowledge of these aspects will assist in the search to identify companies that can satisfy certain material and processing requirements.

Assessing Company Experience and Expertise

This is especially true when it comes to the experience of the workers in delivering the final product. All companies should consider firms that have been in the industry for long. An analysis of the current company’s portfolio and case studies will help the client understand the company’s strengths, the methods used in production, and the achievements of the company.

Industry Specialization

Depending on the type of products they produce, some injection molding companies specialize in certain industries. Such as automotive, medical, or consumer products industries. Companies should consider whether the company specializes in their industry because this will inform the company’s knowledge of the industry norms and guidelines. An industry-specialized company may be in a better position to address the peculiarities of specific applications of the technology.

Evaluation of Quality Assurance Practices

Quality assurance is an essential factor. It should be considered during the injection molding process. Companies need to be confident that the molding partner they have chosen has adequate quality control measures in place. This can be in the form of a schedule of check and test, and accreditation.

Certifications and Standards

Asking about certifications about quality can help businesses get assurance of the quality of a company. The certifications that should be sought by the companies include material safety certifications, environmental management certifications, and quality management system certifications. It is easier for a company that has already implemented quality assurance procedures to deliver quality results.

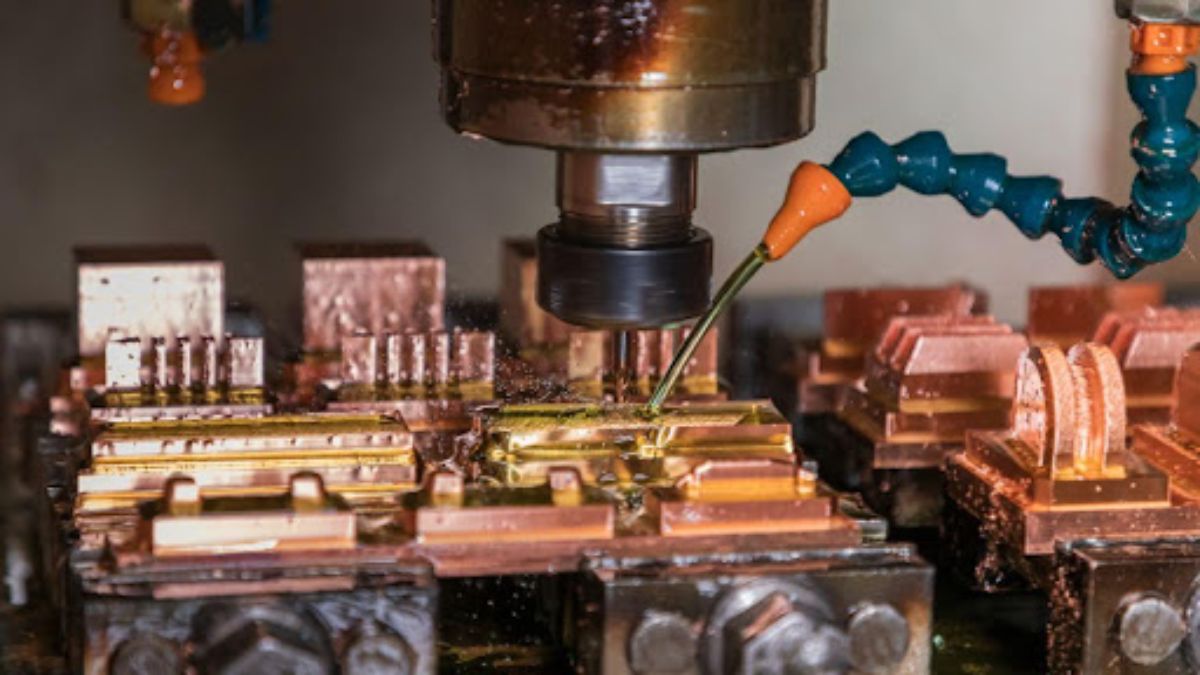

Assessing Production Capacity

The competency of an injection molding company in the manner it conducts its operations influences the duration of a project and its cost. The injection mold manufacturer should consider the machinery and equipment used in the manufacturing process. Contemporary technology with attributes like automatic and precise control can improve the production rate and minimize wastage.

Capacity and Scalability

The capabilities of the company to meet current and future production demands should also be taken into consideration. Companies need to ask the company on how they plan to expand operations depending on the percentage of change in demand. An ideal partner who can address fluctuating production volumes can assist businesses in avoiding unnecessary time wastage and high costs.

Comparing Pricing Structures

However, cost should not be the only decision maker, but it is a very important factor. Businesses should ask various injection molding firms for elaborate quotes to get a clear understanding of the prices. Quotes should also incorporate the cost of materials, labor charges, tooling, and other services provided.

Understanding Value vs. Cost

Any business must understand that the cheapest solution is not always the most effective one. Businesses should consider the life cycle cost, which includes the quality, dependability, and service support costs of the product. Paying a little extra for a service may prove to be financially more beneficial in the long run because it means that the product will not need to be replaced as often since it will not be of poor quality.

Assessing the Communication and Customer Service

It is therefore important that good communication is achieved for the partnership to work. Businesses should also consider how receptive and proactive potential injection molding companies are during the first stages of contact. A company that is keen on its customer service is likely to be more active in the production process.

Developing a Partnership

The opportunity to work with an injection molding partner can be more effective if the organization develops a cooperative partnership with the supplier. Businesses should look for associates who are interested in being responsive, giving regular reports, and responding to issues quickly. Of course, a good relationship between two companies leads to the effectiveness of the development process.

Samples and Prototype Request

Businesses should ask for samples or models from prospective injection molding companies before they make their final decision. This is a good chance to check the quality of work done by them. A prototype can also be used to determine whether any design problems may arise when the product is fully produced.

Relevance of the Iterative Feedback

It is possible to request prototypes so that the business can give feedback to get the product of their desire. This iterative process can help avoid expensive errors and hold up on the product’s manufacturing process. A company that highly considers the opinions of its customers will most likely develop a better product at the end of the process.

Conclusion

The selection of the right injection molding company is not a simple process that involves the consideration of several factors. In this way, the requirements of the projects are described, experience is assessed, quality assurance practices are estimated, and pricing strategies are identified, which will help to make the right decision. Proper communication and cooperation still improve the likelihood of a successful partnership. In conclusion, it is important to choose the right injection molding manufacturer as it will affect the quality of the product, time and efficiency of production, and the success of a business.