In the world of statistical process control (SPC), understanding various charting techniques is critical for monitoring and improving production processes. One such important chart is the XBar (or X-bar) chart, a fundamental tool for understanding process variations. This article delves into the concept of a “Rational Subgroup” in the context of an XBar chart, providing a comprehensive explanation and practical insight into its significance. It also includes SEO-optimized headings and subheadings to make the content accessible and easy to follow.

TRENDING

What Eats The River Bushwillow? Natural Predators Explained

What Is An XBar Chart?

Before diving into the concept of Rational Subgroups, it’s important to first understand what an XBar chart is. The XBar chart is a type of control chart used in SPC to monitor the mean of a process over time. It is particularly useful when monitoring processes that produce continuous data.

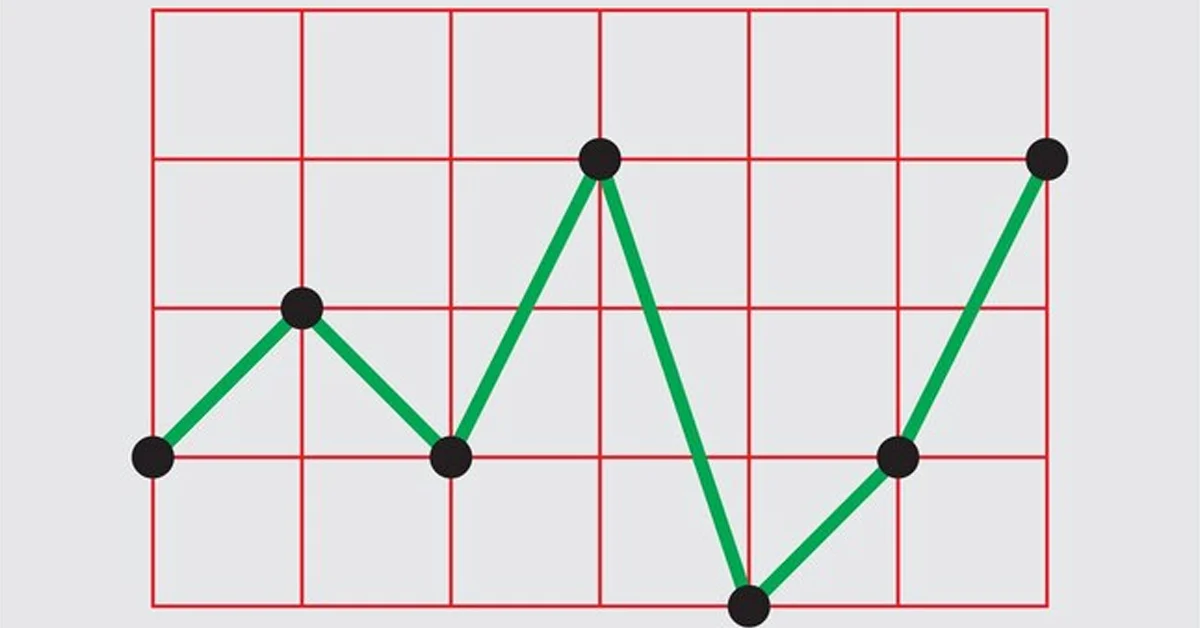

The XBar chart tracks the average value of a process characteristic (e.g., temperature, weight, or length) for a set of samples taken at regular intervals. These sample averages are plotted on the chart, allowing process managers and quality engineers to see if the process is in control or if there are any signs of special cause variation that need to be addressed.

Understanding Rational Subgroups

A Rational Subgroup is a concept that plays a key role in the construction and interpretation of XBar charts. It refers to a group of sample data points that are collected under conditions where only common cause variation is expected to occur. The idea is to group data points in a way that allows the chart to provide meaningful insights into process stability and variability.

Definition of a Rational Subgroup

A Rational Subgroup is a sample set taken at a specific time and under specific conditions, where the variation within the group can be attributed to common causes rather than special causes. Essentially, this means that the variation observed within a subgroup should reflect the inherent variability of the process, not external or abnormal factors.

For example, if you are measuring the weight of a product coming off an assembly line, a Rational Subgroup might consist of several samples taken over a short period of time, all under the same operating conditions. By focusing on these controlled conditions, the subgroup reflects the natural variation of the process rather than any unexpected disturbances.

The Importance of Rational Subgroups in XBar Charts

Rational Subgroups play an integral role in maintaining the integrity of the data in an XBar chart. These subgroups allow you to identify whether a process is behaving consistently or if there are shifts in the process mean due to factors like machine malfunctions, material changes, or operator errors.

In a proper XBar chart, data points that are grouped rationally will show variation that is purely attributable to common causes. This makes it easier to detect when something out of the ordinary (a special cause) occurs. Without rational subgroups, it would be difficult to differentiate between common cause variation and special cause variation, leading to inaccurate conclusions.

Characteristics Of A Rational Subgroup

To construct a Rational Subgroup for an XBar chart, several key characteristics must be considered:

Homogeneity of Conditions

All items in a Rational Subgroup must come from similar conditions. This means that factors like time, temperature, and machine settings should remain constant for all items in the subgroup. By ensuring that all items are produced under the same conditions, the variation seen in the subgroup is likely to be the result of the natural variability of the process.

Consistent Sampling Interval

The samples for a Rational Subgroup should be taken at regular intervals, which helps maintain the representativeness of the data. Irregular sampling can introduce bias and make it difficult to assess the stability of the process over time.

Control of External Factors

External factors, such as environmental conditions or shifts in supply chain variables, should be controlled as much as possible. If external conditions change during the sampling process, the subgroup may no longer reflect the true natural variation of the process.

Sample Size

The sample size for a Rational Subgroup should be large enough to provide a reliable estimate of the process mean and variability. Typically, a subgroup should consist of between 3 and 5 samples, but this can vary depending on the specific process being measured.

Temporal Grouping

Samples within a Rational Subgroup are typically taken within a short time frame. This ensures that the data points are closely related in terms of when they were collected, minimizing the possibility of time-related variability impacting the data.

How To Construct A Rational Subgroup For An XBar Chart

Creating a Rational Subgroup for an XBar chart requires careful consideration of the factors mentioned above. Here’s a step-by-step process for constructing a Rational Subgroup:

Define the Process Characteristic: Identify the characteristic you want to monitor (e.g., product weight, temperature).

Select Sampling Method: Choose a sampling method that ensures random and representative samples from the process.

Determine Sample Size: Decide on an appropriate sample size for each subgroup. Generally, 3-5 samples work well, but this may vary depending on the process.

Establish Sampling Frequency: Determine how often samples will be taken to ensure continuous monitoring of the process.

Monitor Process Stability: Ensure that the conditions under which the samples are collected remain stable, avoiding any external disruptions that might affect the data.

Rational Subgroups Vs. Non-Rational Subgroups

It’s important to differentiate between Rational Subgroups and non-rational subgroups. While Rational Subgroups are designed to capture only the common cause variation of a process, non-rational subgroups may include samples collected under varying conditions, leading to a mix of common and special cause variations.

For example, if an XBar chart is constructed from subgroups that were sampled during periods of equipment maintenance, operator changeovers, or fluctuations in raw material quality, the data will not reflect the true process behavior. This would undermine the ability of the chart to detect process shifts or instability.

Benefits Of Using Rational Subgroups In XBar Charts

There are several advantages to using Rational Subgroups in the creation and interpretation of XBar charts:

Accurate Process Monitoring

By grouping data in a rational manner, you ensure that the XBar chart accurately reflects the inherent variability of the process. This leads to more reliable conclusions about process stability.

Effective Detection of Special Causes

Rational Subgroups help in identifying when special causes of variation are present. These causes could include equipment malfunctions, changes in material quality, or human errors, which may not be immediately obvious without proper subgrouping.

Better Decision Making

With accurate data that reflects the true process behavior, managers can make informed decisions about process improvements. This can lead to enhanced product quality, reduced waste, and improved overall efficiency.

Common Mistakes In Rational Subgroup Selection

While selecting Rational Subgroups might seem straightforward, there are common mistakes to watch out for:

- Inconsistent Sampling: Not collecting samples at regular intervals or not maintaining stable process conditions can result in unreliable subgroup data.

- Incorrect Sample Size: Using too few samples or too many samples in a subgroup can distort the variability calculations, leading to incorrect conclusions.

- Failure to Account for Special Causes: Occasionally, special causes may still occur even in a rationally selected subgroup. If these causes are not identified, they can compromise the validity of the XBar chart.

Conclusion

A Rational Subgroup is a critical concept when constructing an XBar chart, as it ensures that the data reflects only common cause variation and provides an accurate picture of process stability. By carefully defining the subgroup, considering the characteristics of the process, and avoiding common mistakes, manufacturers and quality control specialists can utilize XBar charts effectively to monitor and improve their processes.

ALSO READ: What Eats Suckermouth Catfish? Top Predators Revealed

FAQs

What is a Rational Subgroup in an XBar Chart?

A Rational Subgroup in an XBar chart refers to a group of samples taken under similar conditions where only common cause variation is expected. This ensures that the variation within the subgroup reflects the natural variability of the process.

How do Rational Subgroups help in process monitoring?

Rational Subgroups help in process monitoring by ensuring that the data used in the XBar chart accurately represents common cause variation. This enables better detection of process shifts and special cause variation.

Can a Rational Subgroup contain more than five samples?

Yes, a Rational Subgroup can contain more than five samples, but typically, subgroups of 3 to 5 samples are most commonly used for accurate monitoring without overwhelming the analysis.

What happens if you don’t use Rational Subgroups?

If Rational Subgroups are not used, the data may be influenced by special causes or external factors, making it difficult to interpret the true variation in the process and potentially leading to incorrect conclusions.

How do I select samples for a Rational Subgroup?

Samples for a Rational Subgroup should be taken under stable, consistent process conditions, at regular intervals, and with careful control of external factors that could introduce special causes of variation.